Specific products are as follows:Aluminium (cold rolled sheet) (cold rolled aluminum sheet)Material 1060, 1100, 1050, 8011, 3003, 3004, 5052, 1145, 5083, 6061,Thickness 0.1mm---680mmWidth 800mm----3300mmAluminium coil (cold rolled coil)Material 1060, 1145, 1050, 12008011, 3003, 3004, 5052, 1100,

Contacter maintenant

Thermal insulation aluminum coil has beautiful, durable and practical functionsThe thermal insulation data can be closely connected with the decoration data, so the problem that the thermal insulation data can not be closely connected with the decoration data is solved After contact, it is not easy to fall or loosen, and enhances the wind pressure resistance of the decoration surface data The decoration surface is also diversified in color, and can be processed into various plate shapes, which can better show the characteristics of construction and decoration.

Contacter maintenant

1. Thermal insulation aluminum coil has beautiful and durable functionsThe thermal insulation data can be closely linked with the decoration surface data, so the problem that the thermal insulation data cannot be closely linked with the decoration surface data has been solved. It is not easy to drop or loosen after contact, and the wind pressure resistance of the decoration surface data has been enhanced. The decoration surface has diversified colors, and can be processed into a forest of plates, which can better represent the characteristics of construction and decoration2.

Contacter maintenant

Aluminum sheet is one of all aluminum products, which is called aluminum roll or aluminum strip in professional terms. Aluminum sheet is a kind of non-ferrous metal with high aluminum content. It is often used in various large chemical plants, power plants, pharmaceutical plants, oil refineries and other enterprises. It is one of the building materials for thermal insulation and corrosion protection. Aluminum sheet is the embodiment of aluminum ingot. It is repeatedly processed into rough cast roll through massive aluminum ingot.

Contacter maintenant

The insulation aluminum coil has the function of two layers of insulationTo test the two-layer insulation of the insulation aluminum coil, an aluminum foil is attached to the upper mold of the polyurethane foam. After the foam is formed, the aluminum foil acts as a release agent, while the other side is concerned with the foam, enhancing the wind pressure resistance of the aluminum plate It is enough to illustrate the two-layer thermal insulation of thermal insulation aluminum coil It is highly decorative and different from the structure of other insulation boards at home and abroad.

Contacter maintenant

Basic InstructionThe aluminum plate of the anode is oxidized and a skinny layer of alumina is fashioned at the surface. The anodized aluminum plate improves its hardness and located on resistance, well warmth resistance, the melting detail of tough anodized movie is as masses as 2320k, exquisite insulation, breakdown voltage resistance is as masses as 2000V, complements the corrosion resistance, and does not corrode in high-electricity salt spray for loads of hours.

Contacter maintenant

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is formed on the surface. The anodized aluminum plate improves its hardness and placed on resistance, nicely heat resistance, the melting element of hard anodized film is as plenty as 2320k, superb insulation, breakdown voltage resistance is as plenty as 2000V, enhances the corrosion resistance, and does now not corrode in high-power salt spray for masses of hours.

Contacter maintenant

Aluminum manufacturer,Cheap aluminum sheet,Good quality aluminum plate3003 aluminum plate used for oil tank, gas or oil duct, and other various liquid containers made of deep drawing parts: small load wire used for rivet, kitchen utensils and appliances, food and chemical products processing and storage device, the transportation of liquid product tank, tank, with thin plate processing all kinds of pressure vessel and pipeline General items, heat sink, makeup, copy machine roller, ship material.

Contacter maintenant

purpose1. Lighting 2. Solar reflector 3. Building appearance 4. Interior decoration: ceiling, wall, etc. 5. Furniture, cabinets 6. Elevator 7. Signs, nameplates, bags 8. Interior and exterior decoration of cars 9. Interior decoration: such as photo frames 10. Household appliances: refrigerators, microwave ovens, audio equipment, etc. 11. Aerospace and military aspects, such as China's large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc. 12. Mechanical parts processing 13, mold manufacturing 14, chemical/thermal insulation pipe coating. 15. High quality ship plate

Contacter maintenant

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is ready 50-60% of that of copper, this is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, further to car cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, this is an vital characteristic for electric powered organization and virtual organization. Aluminum profiles cannot spontaneously ignite, this is vital for packages regarding handling or contacting flammable and explosive materials.Installation lap diagramSpecification

Contacter maintenant

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is also known as pipe wrapped aluminum coil.

Contacter maintenant

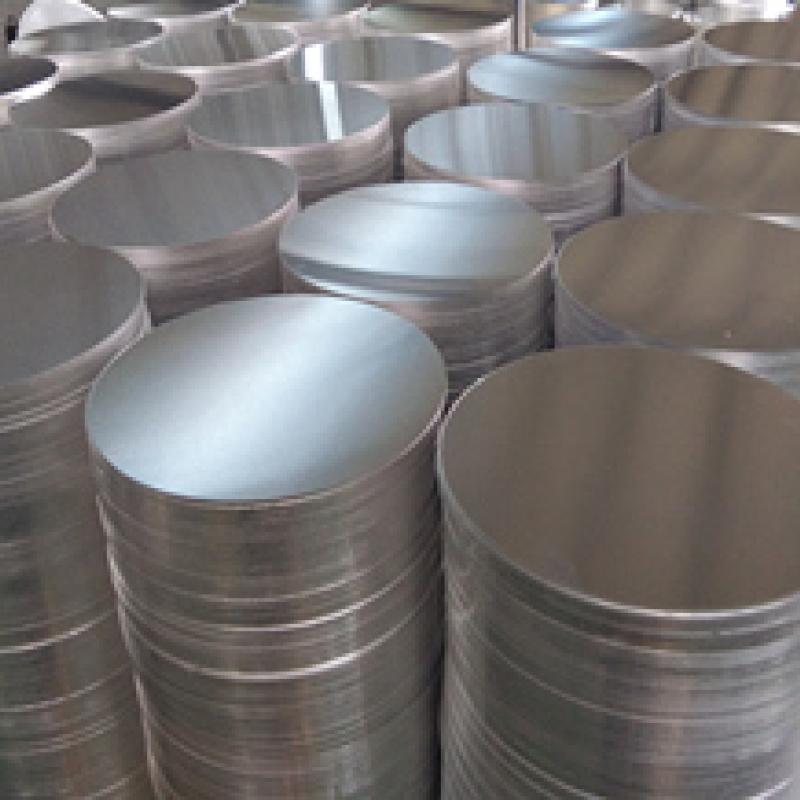

The main components of the aluminum wafer uncoiling and blanking production line are: loading trolley, uncoiler, leveling machine, feeder, swing unit, special closed single point mechanical press, rapid mold change device, stacking unit, waste cutting, hydraulic system, electrical control system, etc.Technical parameters of production line:Coil width (mm): 500-1250800-14001000-1600Coil thickness (mm): 0.4-3.0, 1.0-6.0Coil weight (kg): 8000010000Blanking diameter (mm): 85-660, 85-750100-900Blanking times (spm): 40-55Nominal pressure of press (kN): 1250160020002500Alloy stateMost of them are 1-s

Contacter maintenant

advantage(1) Good processability: the positive grade aluminum oxide plate has strong decorative property and moderate hardness. It can be easily bent and formed, and can be continuously pressed at high speed. It is convenient to directly process into products without complex surface treatment, which greatly reduces the product production cycle and reduces the product production cost.(2) Good weather resistance: standard thickness oxide film (3 μ m) The anodized aluminum plate can be used indoors for a long time without discoloration, corrosion, oxidation and rust.

Contacter maintenant

FeaturesThermal conductivityThe thermal conductivity of aluminum alloy is prepared 50-60% of that of copper, that is useful to the manufacture of warmth exchangers, evaporators, heating appliances, cooking utensils, similarly to vehicle cylinder heads and radiators.Non ferromagnetismAluminum profile is non ferromagnetic, that is an critical feature for electric enterprise and digital enterprise.

Contacter maintenant

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise referred to as pipe wrapped aluminum coil. There is rock wool insulation layer withinside the wrapped aluminum coil and pipe to shield the thermal diffusion of heating pipe, so it's far referred to as thermal insulation aluminum coil. Thermal insulation aluminum coil typically adopts 1100 aluminum coil and 1060 Aluminum Coil. If the carrier necessities are excessive and the carrier lifestyles is long, 3003 antirust aluminum coil may be used.

Contacter maintenant

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise known as pipe wrapped aluminum coil. there's rock wool insulation layer in the wrapped aluminum coil and pipe to defend the thermal diffusion of heating pipe, so it is known as thermal insulation aluminum coil. thermal insulation aluminum coil commonly adopts 1100 aluminum coil and 1060 aluminum coil. if the provider necessities are excessive and the provider life is lengthy, 3003 antirust aluminum coil may be used.

Contacter maintenant

The regular thickness of the heat insulation aluminum sheet pattern aluminum coil pattern aluminum plate embossed aluminum sheet heat insulation aluminum coil is 0.2 mm 0.3 mm 0.4 mm 0.5 mm 0.6 mm 0.7 mm 0.8 mm 0.9 mm. Characteristics of aluminum coil1. The aluminum coil is light in weight. When the price per square meter is calculated, steel and aluminum are almost equal.2. The aluminum coil is easy to process and form, and the construction is convenient and fast, which will reduce the labor intensity of the construction personnel.3.

Contacter maintenant

Thermal insulation aluminum sheet is commonly used in several specifications, generally with a width of 1000mm-2000mm. Other widths are also used, but not particularly. The thickness of aluminum sheet is usually 0.3mm-1.0mm. The length of aluminum sheet is generally divided into two types, one is a large roll of about three tons, which is suitable for large-scale operation, and the other is a small roll of about 50 meters, which is suitable for use in a small space. It is very convenient for two people to use a roll weighing between 50kg and 80kg.

Contacter maintenant

Basic InstructionThe aluminum plate of the anode is oxidized and a thin layer of alumina is long-established on the surface. The anodized aluminum plate improves its hardness and placed on resistance, appropriate warmth resistance, the melting component of hard anodized film is as a lot as 2320k, incredible insulation, breakdown voltage resistance is as a lot as 2000V, enhances the corrosion resistance, and does now now not corrode in high-energy salt spray for loads of hours.

Contacter maintenant

Basic InstructionThe aluminum plate of the anode is oxidized and a skinny layer of alumina is shaped at the surface. The anodized aluminum plate improves its hardness and put on resistance, properly warmness resistance, the melting factor of difficult anodized movie is as much as 2320k, first rate insulation, breakdown voltage resistance is as much as 2000V, complements the corrosion resistance, and does now no longer corrode in high-electricity salt spray for hundreds of hours.

Contacter maintenant

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is also referred to as pipe wrapped aluminum coil. there's rock wool insulation layer inside the wrapped aluminum coil and pipe to defend the thermal diffusion of heating pipe, so it is known as thermal insulation aluminum coil. thermal insulation aluminum coil commonly adopts 1100 aluminum coil and 1060 aluminum coil. if the company necessities are immoderate and the company existence is prolonged, 3003 antirust aluminum coil may be used.

Contacter maintenant

Orange skin pattern and diamond shaped aluminum alloy pattern coil: commonly used for packaging pipes or outer packaging.The orange peel aluminum alloy pattern coil is divided into: Classic orange peel pattern aluminum coil, and variant orange peel pattern aluminum coil (also known as insect pattern). Its surface is similar to orange peel pattern, so it can also be called orange peel pattern aluminum plate.

Contacter maintenant

Basic InstructionThermal insulation aluminum coil thermal insulation aluminum coil is likewise known as pipe wrapped aluminum coil. there is rock wool insulation layer in the wrapped aluminum coil and pipe to guard the thermal diffusion of heating pipe, so it is known as thermal insulation aluminum coil. thermal insulation aluminum coil usually adopts 1100 aluminum coil and 1060 aluminum coil. if the company requirements are excessive and the issuer life is prolonged, 3003 antirust aluminum coil can be used.

Contacter maintenant

How to judge the quality of aluminum brick 1. Observe whether there are multiple scratches on the surface of the aluminum corrugated plate. Aluminum ceramic tile belongs to mechanical processing, which will inevitably lead to some scratches and scratches, but if it is too much, the beauty will be affected. Friends who have high requirements for the surface of aluminum ceramic tiles can also ask the manufacturer to carry out film coating processing in advance. 2.

Contacter maintenant